Annealing Applications

Annealing is the most commonly used for treating metals, but other materials, including glass and plastics, can be annealed. Depending on the

material, annealing temperatures range from less than 100 degrees C to more than 1000°C., a process that can take hours or several days.

During the annealing process, a metal, plastic or glass is heated to a specifi c temperature or color and then the metal is cooled at a controlled,

specifi ed rate. This process changes the physical and chemical properties of the material to make it more malleable, or improve ductility; provide

stress relief and create a new microstructure.

During the annealing process, a metal, plastic or glass is heated to a specifi c temperature or color and then the metal is cooled at a controlled,

specifi ed rate. This process changes the physical and chemical properties of the material to make it more malleable, or improve ductility; provide

stress relief and create a new microstructure.

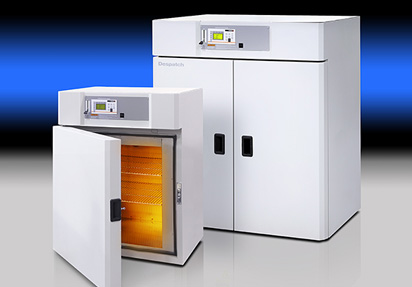

A specialized annealing oven gives users the ability to tightly control and monitor the heating and cooling process, allowing for proper recrystallization

to occur within the material. The materials are annealed at the eutectic point and then allowed to cool. Annealing often softens the materials

so they can be shaped or cut more easily, but can also increase its strength and ductility. Metals are often annealed to prepare them for further

heat treatments.

Annealing Metal PipesThe environment; temperature maintained, both

during and after the annealing process; and cooling rate are critical. Typical

temperatures used in heat treating the most common materials include:

- Steel – 150°C to 1232°C

- Stainless Steel – 345°C to 400°C

- Aluminum – 90°C to 775°C

- Copper – 120°C and up to 800°C

- Plastics – 77°C and up to 260°C

Annealing Plastics

Annealing is not required in all plastic molding; some stresses can be eliminated without the annealing process, depending on the design and materials.

Annealing plastics is recommended based on the following conditions:

- If the end-use conditions are demanding enough to require stress relief beyond what can be achieved through the product design,

process and material

- If stress relief after machining is necessary.

- If during the post polishing process the material would likely crack due to surfaces stresses caused by the polishing itself.

These are usually non-uniformed stresses that can lead to premature failure.

Advantages of Annealing Plastics Plastics that have been stress relieved offer:

These are usually non-uniformed stresses that can lead to premature failure.

Advantages of Annealing Plastics Plastics that have been stress relieved offer:

- Tighter toleranc

- Improved chemical resistance

- Improved wear resistance

- Improved flatness control

- Better able to handle machined stress

Plastics require different annealing conditions and temperatures:

- Polycarbonate: 250°F(121°C) for as short a time as possible determined through experimenting with test data

- Ultem: slowly brought up to 400°F(204°C) and then held for two hours

- ABS materials: heat deflection temperature at 264 psi (170°F to 240°F) and held for 1-2 hours.

- Supec resins: Annealed at 400°F(204°C) for 4 hours

You may also be interested in:

During the annealing process, a metal, plastic or glass is heated to a specifi c temperature or color and then the metal is cooled at a controlled,

specifi ed rate. This process changes the physical and chemical properties of the material to make it more malleable, or improve ductility; provide

stress relief and create a new microstructure.

During the annealing process, a metal, plastic or glass is heated to a specifi c temperature or color and then the metal is cooled at a controlled,

specifi ed rate. This process changes the physical and chemical properties of the material to make it more malleable, or improve ductility; provide

stress relief and create a new microstructure. These are usually non-uniformed stresses that can lead to premature failure.

Advantages of Annealing Plastics Plastics that have been stress relieved offer:

These are usually non-uniformed stresses that can lead to premature failure.

Advantages of Annealing Plastics Plastics that have been stress relieved offer: