ELECTRONIC COMPONENTS

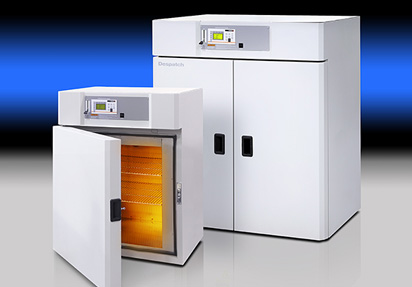

Despatch has successfully addressed the many technical challenges of thermal processing for capacitors, resistors and other electronic components used in cell phones, disc players, televisions and other devices.

From ceramic capacitor bakeout to preheating, drying and curing, Despatch provides the uniform temperatures and gradual ramp rates that are essential to these processes. Despatch ovens can control air velocities, either up or down, at ±5% or better, with temperature uniformity at ±5°C or better.

BURN-IN AND TESTING

Integrated Circuits (IC’s) and other electronic devices are burned in at elevated temperatures to stress and exercise the devices under test. The high temperatures force early failure, known as “infant mortality”, at this point rather than later when they are in use in a finished product. This dramatically improves the reliability of the product.

Despatch has developed a strong reputation in the burn-in market over the last 30 years and has thousands of systems in operation throughout the world. The system’s proven reliability and ability to meet uniformity requirements has helped build that reputation. Having worked closely with this industry for many years has also allowed Despatch to understand the unique needs of the end users.

SEMICONDUCTOR MANUFACTURING

Despatch is the world’s premier supplier for clean process, low oxygen, fast cycle curing of adhesives and polymers used in high-volume semiconductor packaging and assembly.

- Superior temperature uniformity of ± 0.5% of setpoint

- SEMI S2/S8, CE, SECS/GEM communication

- Low particulate environmental controls to protect contamination

- Low oxygen levels to prevent oxidation

APPLICATIONS

Electronic Devices and Semiconductor: Adhesive bonding and curing, Encapsulant curing, Underfill curing of CMOS optical sensors, Die attach and BGA, B-Stage adhesive curing, Reliability testing, Polyimide curing, Burn-in and testing, Metalic thin film annealing, Polyimide curing, Photoresist curing, Reliability testing

Electronic Components: Pre-Heating, Bake Out, Drying, Curing, Annealing, Solder Reflow

You may also be interested in: