Despatch offers a selection of benchtop, cabinet, walk-in and conveyor ovens that are ideal for curing applications. Despatch curing ovens offer fast ramping and cool down rates for maximum productivity, short cycle times and consistent, reproducible curing processes for all product loads.

Curing ovens are used for a variety of applications involving coatings, adhesives, rubber and thermoset plastics and composites. The electronics and semiconductor industries use Despatch clean process ovens for epoxy curing and polyimide curing. Despatch specializes in polyimide curing ovens that are designed to meet the unique process requirements for hard baking polyimide coatings in an inert atmosphere.

Despatch curing ovens are designed to provide tight temperature tolerance and precise control for repeatable results and uniform airflow that ensure proper curing across an entire load. The ovens are exhausted to effectively remove the VOCs given off during curing, ensuring a safe environment. Best-in-class energy efficiency is achieved with superior insulation and cabinet design as well as recirculating airflow management. Despatch offers gas or electric batch ovens for curing small to very large loads and conveyor ovens with multiple zones for continuous processing. If your process requires a custom solution, we can work with you to create a configuration that suits your specific needs.

Large Capacity Walk-In Ovens

The 476 and 952 cubic foot capacity Despatch TAD/TFD walk-in ovens feature uniflow airflow to ensure uniform temperatures throughout the oven. This air moves horizontally and vertically through the work chamber making it the perfect solution for curing applications. Maximum temperature is 343°C (650°F). These ovens ship in just 6 weeks.

LEARN MORE

REQUEST A QUOTE

PRC Catheter Curing Oven

Designed specifically to address the unique requirements of catheter manufacturers. The oven features vertical airflow to keep cross wind from blowing tubes around, a tall configuration with a small footprint to save floor space while allowing room to hang catheters up to 80 inches long inside the chamber, and a stainless-steel interior for easy cleaning.

LEARN MORE

REQUEST A QUOTE

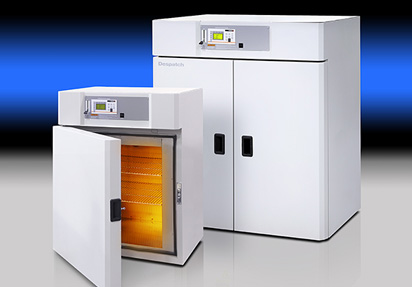

LAC High Performance Benchtop Ovens

The LAC benchtop oven features horizontal recirculating airflow and exceptional temperature uniformity. The result is proven reliability in demanding production and laboratory applications, such as curing, drying, sterilizing, aging, and other process-critical procedures.

LEARN MORE

REQUEST A QUOTE

LBB Forced Convection Benchtop Oven

The Despatch LBB forced convection benchtop oven features a combination of horizontal and vertical airflow that offers excellent temperature uniformity at a moderate price. It is recommended for a variety of laboratory and production applications including drying, curing, annealing and materials testing.

LEARN MORE

REQUEST A QUOTE

LCC2-14 & LCD2-14 Clean Process

Despatch’s LCC/LCD2-14 Clean Process Cabinet Ovens are designed to meet the demands of production and large scale R&D environments. A variety of tailored options are available to meet your specific needs. Typical applications for these ovens include die-bond curing and other semiconductor packaging processes, depyrogenation, sterilizing and drying for life sciences.

LEARN MORE

REQUEST A QUOTE

PC Series Conveyor Ovens

Despatch PC Series Conveyor Ovens are designed for process versatility and reliability. They achieve superior temperature uniformity in all interior parts due to high-volume, vertical down airflow. The continuous belt design is ideal for large quantities of similar work pieces being processed.

LEARN MORE

REQUEST A QUOTE

RA and RF Cabinet Ovens

The RA/RF cabinet oven features horizontal recirculating airflow and exceptional temperature uniformity. The result is proven reliability in demanding production and laboratory applications, such as curing, drying, sterilizing, aging, ASTM testing, UL testing and other process-critical applications.

LEARN MORE

REQUEST A QUOTE

TA and TF Walk-In Ovens and Truck-In Ovens

The TA and TF Walk-In Ovens and Truck-In Ovens are designed for industrial process versatility and dependability. Typical applications include aging, bonding, curing, drying, baking, heat treating, annealing and stress-relieving.

LEARN MORE

REQUEST A QUOTE

PCO2-14™ Polyimide Curing Oven

The PCO2-14™ Polyimide Cure solution is a clean process oven designed for electronics market applications that require low oxygen: polyimide and epoxy curing, baking and sterilizing. The PCO2-14™ optimizes the polyimide curing process for semiconductor wafer devices.

LEARN MORE

REQUEST A QUOTE

Composite Curing

Despatch offers a wide range of standard and custom ovens for composite curing. The ovens provide uniflow airflow which delivers heated air from both sides of the chamber for uniform operating temperatures. Typical applications include curing filament-wound composites used in products such as light weight pressure vessels, and curing the composite components of wind turbine blades. Despatch is an established supplier of vacuum bag composite curing systems with numerous systems installed at many of the major aerospace manufacturers.

Curing Medical Device Adhesives

Curing Medical Device Adhesives

Custom Curing Ovens

Conveyor Oven for Curing Eyeglass Lens Coatings

An optical manufacturer needed a conveyorized thermal processing oven to dry the coatings on its eyeglass lenses. Despatch designed a custom PC Series conveyor oven with HEPA filtration to meet the customer’s requirements for high-volume production while maintaining a clean internal atmosphere.

The conveyor oven operates at relatively low temperatures and was designed to be compatible with the customer’s robotic loading equipment. The PC Series Conveyor Oven features superior temperature uniformity with temperatures up to 260°C (500°F). Conveyor speeds are variable and Class A models are available.

You may also be interested in: