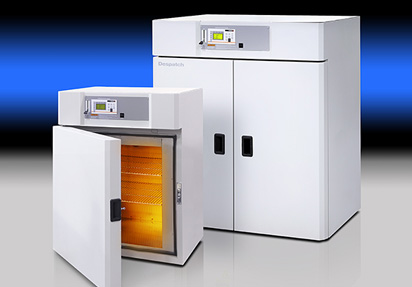

Despatch lab ovens feature horizontal airflow which delivers uniform heating across all shelves, whereas most lab ovens utilize vertical airflow. A high-volume fan circulates air through perforated, stainless steel walls to create a constant horizontal airflow across all sections of the oven. These lab ovens provide controlled ramp rates with the capacity to rapidly bring the product up to the desired temperature for shorter cycle times.

Despatch lab ovens are easy to clean with stainless steel interiors and smooth door surfaces. They feature sturdy, welded, double-wall construction, thick glass fiber insulation, and heavy-duty door gaskets. Each oven receives a thorough quality and performance test before it is shipped. Heating elements carry a five-year warranty.

Every Despatch lab oven except the LBB series feature the Protocol 3™ microprocessor-based temperature and hi-limit controller with a large LCD display. The data-logging functionality enables reporting and analyzing, and data files can be exported via the controller's USB port. You can control the oven from your computer with optional software that also records operating information, including times, temperatures, set points, alarm conditions, and lot numbers. Data is written in an editable form that can be easily saved in an Excel format.

Clean process laboratory applications

For lab environment processes where minimal contamination is essential, an LCC or LCD Series lab oven offers the highest standard in HEPA filtration. Re-circulated airflow is 100% HEPA filtered for operation at ISO Class 5 (Class 100) or better within the oven chamber.

Typical applications for these ovens include die-bond curing and other semiconductor packaging processes, depyrogenation, sterilizing and drying for life sciences. These units are stackable to save valuable floor space and provide maximum ergonomic efficiency for operators.

This oven is available with inert Atmosphere. Nitrogen (or other inert gas) is injected into the chamber to lower the oxygen level to prevent oxidation of products. A water cooling coil is provided for rapid cooling.

Lab Ovens for Hazardous Areas and Flammable Solvents

Special design features are required when the oven and/or controls will be located in an area classified as hazardous. This classification refers specifically to an explosion hazard from the possible ignition of dust, vapors or gas in the area external to the oven, and is not limited just to volatiles within the oven chamber. Despatch Class A lab ovens are specially designed to meet NFPA 86 requirements. They include a pressure relief panel, purge timer and exhaust fan.

Laboratory ovens for material and reliability testing

Despatch's RBC Burn-In Oven offers maximum flexibility for small lot qualification testing, burn-in, reliability testing, and research and development. The stackable oven allows you to run concurrent tests utilizing different temperatures or different cycle times. They are ideal for qualification testing with small lots, because a new test may be started on the second chamber while the first test is still in progress.

For applications which require 100+ air exchanges each hour Despatch offers the Qmax. This lab oven was specifically designed to meet the frequent air changes and tight temperature uniformity required to meet ASTM 5423 Type I and II specifications. The oven has a temperature variation of less than 6℃ at 300℃ while maintaining 100-200 air changes per hour. This lab oven can be used for applications such as thermal evaluation of electrical insulating materials, testing, aging, curing, drying, sterilizing and other thermal applications where tight temperature uniformity is required.

You may also be interested in: