Annealing Ovens

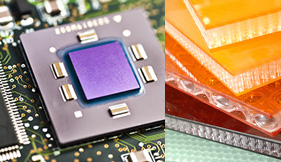

Annealing is most commonly used for treating metals, but other materials, including

glass and plastics, can be annealed. Depending on the material, annealing temperatures

range from less than 100°C to more than 1000°C. Despatch offers a wide selection of

high performance industrial ovens designed for annealing applications.

MORE INFORMATION