SYNTHETIC MATERIALS

Fuel Cells and Batteries

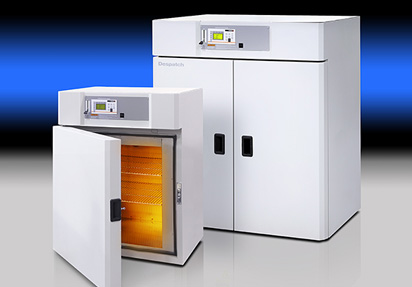

Despatch Industries offers heat treating equipment for the growing fuel cell and energy storage industry. Despatch collaborates with major industry players, providing equipment worldwide. Applications include heat treating materials for both the automotive and energy storage industries.

Oil and Gas

Despatch has become a trusted partner with many companies involved in the exploration for oil. The petroleum/oil industry relies on Despatch Industries for burn-in and performance qualification testing of down-hole electronic logging equipment. Typical processes include simulating down-hole conditions for oil well drilling and calibration.

The PTC Series ovens are well-suited for this industry to accommodate efficiency and productivity. The PTC oven is a forced convection oven designed for heating long and narrow loads such as tubing and extrusions. A space-conscious footprint is combined with removable end caps to allow placement of several ovens end- to-end to accommodate any length requirement.

METALS AND ALLOYS

Despatch ovens and furnaces are used for annealing and hardening copper, steel, aluminum and titanium parts. Despatch equipment processes everything from small staples or fasteners running through a conveyor oven, to large metal structural components that are trucked into a batch oven.

Heat treating often requires processing at high temperatures for extended periods making energy efficiency a high priority. Despatch ovens and furnaces have thick wall insulation, heavy-duty high temperature door gaskets and air that is recirculated through the heater box and back into the chamber for greater energy efficiency. Despatch ovens feature high velocity uniflow airflow, meaning that the air moves both horizontally and vertically, offering exceptional temperature uniformity. Adjustable louvers direct heated air for a precise airflow pattern suited to specific parts. These ovens and furnaces are built to withstand the rigors of industrial metal manufacturing with sturdy, welded, double wall construction.

EQUIPMENT MANUFACTURING

Equipment manufacturers require heat treating equipment for a wide variety of applications. Despatch ovens are used for curing painted finishes, drying solvents and water, annealing plastics and metals and stress testing components. Whether an application requires batch or continuous processing, Despatch offers the highest quality ovens and furnaces with superior temperature uniformity and the durability to withstand the rigors of an industrial manufacturing environment. Despatch has a wealth of experience designing custom ovens and furnaces to suit the unique requirements of our customers.

APPLICATIONS

Equipment Manufacturing

- Annealing

- Curing

- Drying

- Hardening

Metals and Alloys

- Aging

- Annealing

- Hardening

Fuel Cells and Batteries

- Heat treating fuel cell materials for automotive and energy storage

Fossil Fuels

- Calibration tools

- Testing down hole drilling equipment

- Calibration testing of equipment used in oil exploring

- Testing electronic boards using down hole equipment

You may also be interested in: