SYNTHETIC MATERIALS

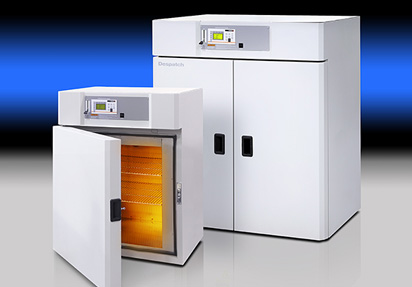

Despatch manufactures a variety of ovens for heat treating synthetic materials such as: thermoset plastics, adhesives, paints and powder coats, rubber and many others. Common applications include:

- Annealing – removes stresses and increases material strength

- Curing – helps materials to cross-link and retain defect-free characteristics

- Drying – provides a faster liquid removal from the material

- Hardening – increases the strength of the material for better resistance to wear

COMPOSITE MATERIALS

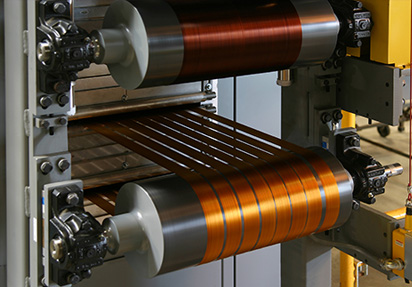

Composite materials are becoming the material of choice for industries such as aerospace, automotive, wind energy, sports and recreation and industrial construction. Carbon fiber composites provide an exceptionally strong and lightweight material needed for reduced energy consumption and durability.

Composite materials are becoming the material of choice for industries such as aerospace, automotive, wind energy, sports and recreation and industrial construction. Carbon fiber composites provide an exceptionally strong and lightweight material needed for reduced energy consumption and durability.

Despatch provides an advanced out-of-autoclave solution to the challenging composite curing process. Despatch composite curing ovens provide uniflow airflow which delivers heated air from both sides of the chamber for uniform operating temperatures. The ovens can be custom designed for an airflow that is best suited to provide the fastest, most uniform heat-up time for any product.

Despatch offers complete vacuum bagging systems with up to 24 vacuum ports. Jack panels allow connection to as many thermocouples as needed for monitoring the curing process. Mold preparation, including preheating, drying and cleaning processes can also be provided.

A control system is available to fully control your vacuum bagging process. A PC software package is utilized to record all the necessary information relating to your thermocouples, vacuum transducers, temperatures, Hi-limits, user access and all related alarms. This system allows full control and ensures parts are reliable and cured to specification.

MATERIALS TESTING

Despatch provides laboratory ovens for testing and analyzing materials such as asphalt, polymers, composites, paint and other coatings. Testing is used to define material characteristics, detecting defects and failure susceptibility. Despatch ovens are highly uniform and repeatable with extremely tight temperature tolerances for consistent testing. For simple applications such as heating soil and asphalt samples prior to quality testing the LBB forced convection oven, with it’s fast heat-up rates and short processing times, is a popular choice. For more sophisticated testing, choose an oven with the microprocessor based Protocol 3TM controller. It provides simple and flexible operation and can be paired with monitoring and data logging software for detailed reporting of oven process data.

Despatch provides laboratory ovens for testing and analyzing materials such as asphalt, polymers, composites, paint and other coatings. Testing is used to define material characteristics, detecting defects and failure susceptibility. Despatch ovens are highly uniform and repeatable with extremely tight temperature tolerances for consistent testing. For simple applications such as heating soil and asphalt samples prior to quality testing the LBB forced convection oven, with it’s fast heat-up rates and short processing times, is a popular choice. For more sophisticated testing, choose an oven with the microprocessor based Protocol 3TM controller. It provides simple and flexible operation and can be paired with monitoring and data logging software for detailed reporting of oven process data.

CARBON FIBER

Despatch provides laboratory ovens for testing and analyzing materials such as asphalt, polymers, composites, paint and other coatings. Testing is used to define material characteristics, detecting defects and failure susceptibility. Despatch ovens are highly uniform and repeatable with extremely tight temperature tolerances for consistent testing. For simple applications such as heating soil and asphalt samples prior to quality testing the LBB forced convection oven, with it’s fast heat-up rates and short processing times, is a popular choice. For more sophisticated testing, choose an oven with the microprocessor based Protocol 3TM controller. It provides simple and flexible operation and can be paired with monitoring and data logging software for detailed reporting of oven process data.

APPLICATIONS

Synthetic Materials

- Annealing

- Curing

- Drying

- hardening

Materials Testing

- Preheating

- Analyzing Characteristics

- Defect Detection

Composite Materials

- Composite Curing

- Curing

- Drying

- Vacuum Bagging

You may also be interested in:

Composite materials are becoming the material of choice for industries such as aerospace, automotive, wind energy, sports and recreation and industrial construction. Carbon fiber composites provide an exceptionally strong and lightweight material needed for reduced energy consumption and durability.

Composite materials are becoming the material of choice for industries such as aerospace, automotive, wind energy, sports and recreation and industrial construction. Carbon fiber composites provide an exceptionally strong and lightweight material needed for reduced energy consumption and durability.

Despatch provides laboratory ovens for testing and analyzing materials such as asphalt, polymers, composites, paint and other coatings. Testing is used to define material characteristics, detecting defects and failure susceptibility. Despatch ovens are highly uniform and repeatable with extremely tight temperature tolerances for consistent testing. For simple applications such as heating soil and asphalt samples prior to quality testing the LBB forced convection oven, with it’s fast heat-up rates and short processing times, is a popular choice. For more sophisticated testing, choose an oven with the microprocessor based Protocol 3TM controller. It provides simple and flexible operation and can be paired with monitoring and data logging software for detailed reporting of oven process data.

Despatch provides laboratory ovens for testing and analyzing materials such as asphalt, polymers, composites, paint and other coatings. Testing is used to define material characteristics, detecting defects and failure susceptibility. Despatch ovens are highly uniform and repeatable with extremely tight temperature tolerances for consistent testing. For simple applications such as heating soil and asphalt samples prior to quality testing the LBB forced convection oven, with it’s fast heat-up rates and short processing times, is a popular choice. For more sophisticated testing, choose an oven with the microprocessor based Protocol 3TM controller. It provides simple and flexible operation and can be paired with monitoring and data logging software for detailed reporting of oven process data.