SAFIRE 3 DUAL CHAMBER FIRING FURNACE WITH DRITECH DRYER AND POWERLOCK

The tools you need for process perfection

The new Safire 3™ is designed and built on the foundation of high throughput mass production equipment with the features of process separation, stability, high uptime and the ability to tailor thermal profiles as the previous version. The redesigned heating/cooling sections and belt movement system ensures the greatest degree of firing repeatability and capability for cell efficiency optimization in a high throughput platform.

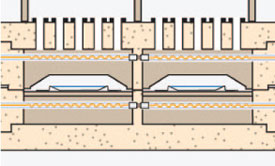

The high-performance Safire firing furnace has segmented and optimized critical components of the cell process for maximum control and stability. The Safire integrated with the DriTech™ dryer decouples VOC removal from the burn-out process and the new oxidizer ensures ultra high VOC destruction efficiency without clogging to prevent furnace and facility contamination. Burn-out is separated from firing for proper binder removal, a contamination-free firing zone and a stable, repeatable thermal experience. The Safire’s dual independent chamber design eliminates lane-to-lane loading influence. The in-situ belt cleaner prevents defects from belt ashes.

The Safire offers further process optimization through Microzone™ Technology. Microzone Technology provides the ability to precisely tailor the burn-out interval, the time above melting temperature and the peak firing. SolectFire™ enables independent temperature control of each specific top and bottom zones enable optimized frontside and backside firing process. The advanced cooling section ensures a rapid, effective cooling process. The advanced features and technology designed into the integrated Safire and DriTech firing and drying system offer a complete solution capable of achieving process perfection with all materials and architectures.

The Safire now features PowerLock™ technology which suppresses LID on PERC cells from 3-6% down to ~1%. The system is integrated into the Safire resulting in a small footprint and no material handling. PowerLock uses LED light that provide twice the lumens per watt and ten times longer life compared to the arc lamps used in other systems on the market.

- Uniform, stable and repeatable

cavity temperature (+/- 2℃) - Dual independent chambers

with no lane to lane influences - Uninterruptible power supply

- Rapid thermal ramping

(up to 250℃/sec) - Enhanced thermal cooling

(up to 200℃/sec) - Up to 15,000 cm/minute belt speed

- Edge contact belt with Ti alloy coating

- Master production control interface

- Enhanced Microzone™ Technology for precise thermal control

- Enhanced SolectFireâ„¢ Technology for top/bottom temperature control

- Data logging and data trending

- DriTech™ Dryer with integrated VOC Thermal Oxidizer

- Hot swappable lamps on furnace

- 99% uptime (highest in the industry)

- Profiling systems

- CE compliance

- PowerLock LID prevention