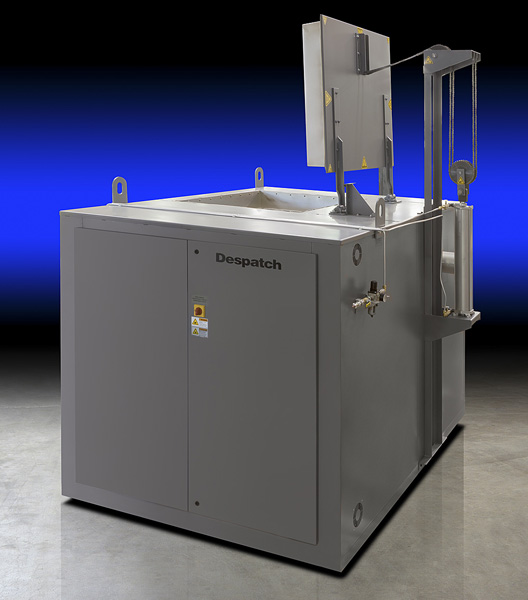

TOP-LOADING HIGH TEMPERATURE OVEN FOR ALUMINUM HEAT TREATING

A customer needed an oven for heat treating aluminum parts at 750℉ with a maximum range up to 850℉. This top-loading oven allows heavy parts to be loaded by an overhead crane. A pneumatically operated swing-up door addresses the problem of accessibility. The floor has a quarter inch plate with a 200 pound load capacity. The 45 cubic foot chamber is constructed with aluminized steel to prevent corrosion. Horizontally recirculated airflow ensures tight temperature uniformity that exceeds customer requirements. Adjustable air distribution louvers direct heated air to the part and is then recirculated through the heater box and back into the oven for greater energy efficiency.

The oven has a Protocol 3™ microprocessor-based temperature and hi-limit controller with large LCD display and real time clock for auto start capability. The LCD display shows temperature readings along with clear, detailed information on oven status. Protocol 3™ features three operating modes for quick and easy operation: Manual mode, Timer mode and Profile mode. The data-logging functionality enables reporting and analyzing and data files can be exported via the controller's USB port.