CABINET OVEN WITH NITROGEN ATMOSPHERE FOR CONTACT LENS CURING

Most high-volume contact lens manufacturers use a cast molding technique in which a monomer resin called “hydrogel” is injected into two-piece polypropylene molds called “cups.” The cups are then heat-cured in an oven to polymerize the hydrogel to produce hard, slightly flexible lenses. The lenses are then removed from the cups and transferred to a downstream hydration process.

These hydrogel thermal curing cycles can be relatively long—up to 34 hours—and require a reliable oven with uniform internal temperatures, an inert nitrogen atmosphere, and accurate ramp and soak time and temperature controls. The Despatch LNB oven offers the ideal solution for contact lens manufacturers and other manufacturers with similar applications.

Despatch LNB Inert Atmosphere Oven: The Despatch LNB oven’s core strength is its process repeatability and reliability. Designed for long service life and low maintenance, Despatch LNB ovens offer consistent performance while taking up minimal floor space. The stainless-steel interior allows easy cleaning and the SilverClay™ baked enamel exterior matches any lab environment.

The LNB’s operating range is from 60°C to 150°C (140°F to 302°F), with horizontal airflow producing superior temperature uniformity. An internal nitrogen atmosphere system is standard and will reduce oxygen concentrations to as low as 1000 ppm as required to prevent distorted or discolored lenses. A purge-flowmeter, maintained-flowmeter and manual three-way valve provide easy and accurate nitrogen flow control.

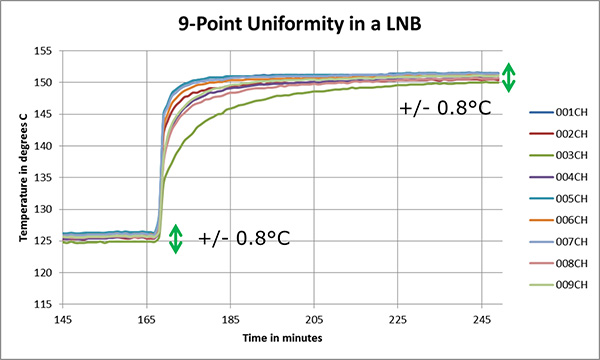

A test was conducted to get a better understanding of temperature uniformity inside a customer’s large LNB chamber (48x50x38in). The chamber was loaded with their product and a nine-point temperature uniformity test was performed. As can be seen in below chart after stabilization a temperature uniformity of +/- 0.8°C was achieved which greatly surpassed the customer requirement of +/- 3°C.