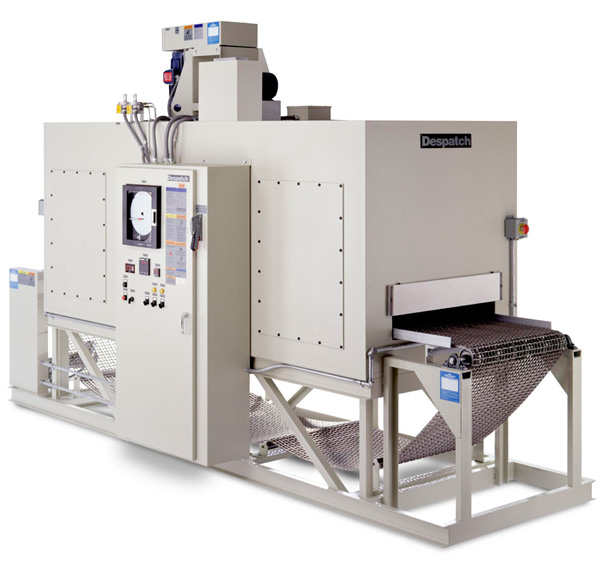

PCC2-15 Conveyor Oven for Battery Bonding

A manufacture of batteries is purchasing two Despatch Conveyor ovens for its automated production line. The ovens are needed to bond materials in the battery assembly inside a mold. The molds are inserted and removed from the conveyor oven with automated pick and place robots. Tight temperature control with very little variance is critical to the process to ensure proper bonding.

The size and performance of the Despatch PCC2-15 conveyor oven provided an ideal solution with only minor modifications needed. The conveyor belt was designed to accommodate up to 15 parts across the width and a load of up to 60 pounds per linear foot. Attachment links were added to interface with the customer’s fixtures. A Watlow EZ Zone controller with PID and custom sensors were added to allow communication with the automation system. This was a big win for ITW EAE and resulted from the excellent reputation of the Despatch brand and the relationships developed by our sales representatives. The company has plans to order as many as 40 more of these ovens to meet growing demand.