INTEGRATED CARBON FIBER LINE SOFTWARE CONTROL SYSTEM

INDUSTRY SPECIFIC PLC CONTROL SYSTEM FOR PRECISE CONTROL AND FLEXIBILITY OF PRODUCTION LINES

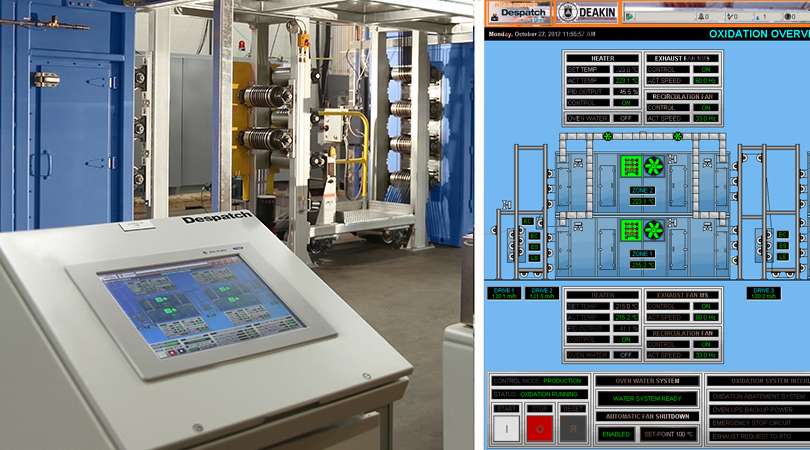

Despatch’s integrated process control software system offers differentiated technology and control functionality not available from any other carbon fiber equipment provider. Despatch’s integrated PLC control system software is written by industry experts with more than fifteen years of experience writing code for systems specifically designed to run carbon fiber production lines. Applying this knowledge and insight to create the control software allows Despatch to offer a carbon fiber specific integrated system that is tightly tied to the critical needs of the customer.

Oxidation is the most critical process step in the production of carbon fiber. It consumes the most energy, has the largest factory footprint, and is the largest capital investment in a carbon fiber line. Any improvement to this step will have a huge impact on the cost and quality of carbon fiber.

FEATURES OF THE INTEGRATED CONTROL SYSTEM INCLUDE:- Individual HMI consoles at key locations for convenient access

- Full system diagnostics to aid troubleshooting

- Comprehensive alarm system

- Data logging of all real time process parameters and variables

- Clear and intuitive HMI display screens

- Reporting and data logging capabilities

- User access control for operational security

The control system is capable of isolating each equipment subsystem in the line to precisely monitor and control temperature, speed, ramp rates, liquid solution levels, and many more specific performance metrics.