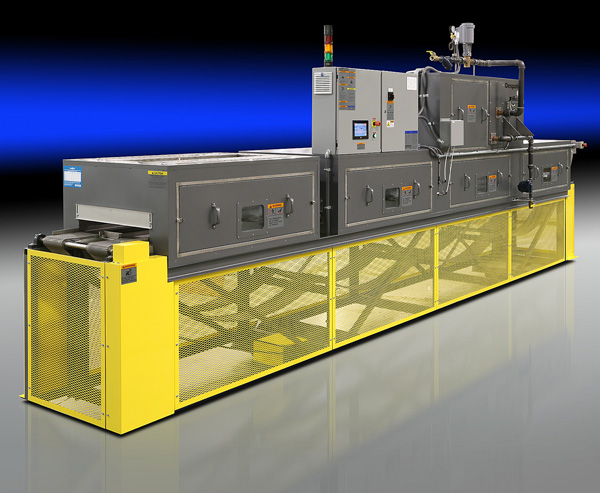

CONVEYOR OVEN FOR IMPACT-SENSITIVE DRYING PROCESS

During manufacture, 22 caliber rimfire cases are filled with an impact-sensitive primer in a wet state so that the primer is stable. This primer then needs to be dried so it will detonate when the gun is fired. A continuous oven with two conveyors that carry pallets containing 300 casings every 8 seconds was requested. The oven uses a steam heat source with an air temperature limited to 185°F with a Hi-limit controller. Primer dust tends to accumulate during processing so the oven needed to have easy access to the interior for cleaning.

Engineers at the Despatch Innovation Center visited the customer site to document the configuration and thermal profile from the existing oven being used for this process. They then ran experiments to optimize oven airflow and verify that the configuration gave superior primer drying results and product quality. This drying oven can also process twice as much product as their existing oven.

A unique air delivery system was developed using perforated aluminum plates to provide better airflow with a lower pressure loss at discharge. Compared to traditional louvers, the plates are easier to clean and are more cost effective.

The oven has a sophisticated temperature control and monitoring system that provides over 20 process programs to accommodate different profiles and products. The program controls belt speed, oven temperature and air velocities and records key parameters for historical record keeping and analysis.